Keox Technologies was given an application by a client where they needed to differentiate colors of powder coated metal. The challenge is that some powder being Electrically Spray Deposited (ESD) were very similar in color such that the human eye cannot easily distinguish the coating result. Additionally, natural process variability of the powder coating process, such as varying film thicknesses, baking temperature variation, and even contamination of the chamber, also affected the final color result.

With the subtle wrong color used, it caused product variations and gave the perception of lesser quality control, especially when parts are placed next to each other. This jeopardized the company’s reputation to their customers. It also created returns and unsellable products, which increased manufacturing costs and negatively affected market share.

Example of product swatches between the “black” samples. Also notice the slight differences in the reflective (specular) surface finishes.

Keox Technologies provided a solution to accurately measure color online, which also took surface texture into consideration. This involved a carefully controlled measurement head, based on spectrometry principles, along with unique image processing techniques.

Black color is especially difficult because not much light gets reflected back into the measurement head and is subject to poor signal-to-noise ratio. Likewise, bright white colors require careful control of the camera gain and illumination intensity.

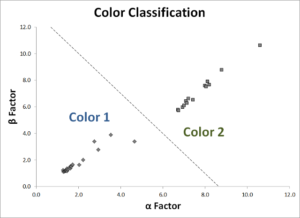

Since one task of the system is to identify which powder coat color was used, Keox elected to use a Linear Classifier instead of a simple threshold differentiator. This ensures robustness and minimizes Type I and Type II errors (false positives and false negatives).